Automatic Olive oil glass bottle filling and capping machine complete olive oil line

Item specifics

- filling head

- 6

- productive capacity

- 10-50pcs/min 4filling nozzles 50-60pcs/min 6 filling nozzles 60-80pcs/min 8 filling nozzles 80-100pcs/min 10 filling nozzles 100-120pcs/min 12 filling nozzles

- filling accuracy

- ±1%

- capping head

- single

- locking head

- single

- handing rate

- ≥98%(It has a certain relationship with the quality of the cover)

- speed control

- Frequency control of motor speed

- Voltage

- 380v,50Hz,1.5kw

- net weight

- 600kg

Review

Description

Automatic Olive oil glass bottle filling and capping machine complete olive oil line

olive oil filling machine---product introduce

The liquid filling and capping machine is widely used in food, medicine, daily chemical, oil and other

industries, and can fill different high viscosity fluids. The machine design is compact and reasonable,

the appearance is simple and beautiful, and the filling volume is easy to adjust. This equipment

improves the design on the basis of a series of products, such as filling, capping, hanging, and

locking, and adds some additional functions. Make the product more simple and convenient in

operation, such as accuracy error, installation adjustment, equipment cleaning, maintenance and so

on.

olive oil bottle filling machine---technical parameter

| filling head | 6 |

| productive capacity | 10-50pcs/min 4filling nozzles 50-60pcs/min 6 filling nozzles 60-80pcs/min 8 filling nozzles 80-100pcs/min 10 filling nozzles 100-120pcs/min 12 filling nozzles |

| filling accuracy | ±1% |

| capping head | single |

| locking head | single |

| handing rate | ≥98%(It has a certain relationship with the quality of the cover) |

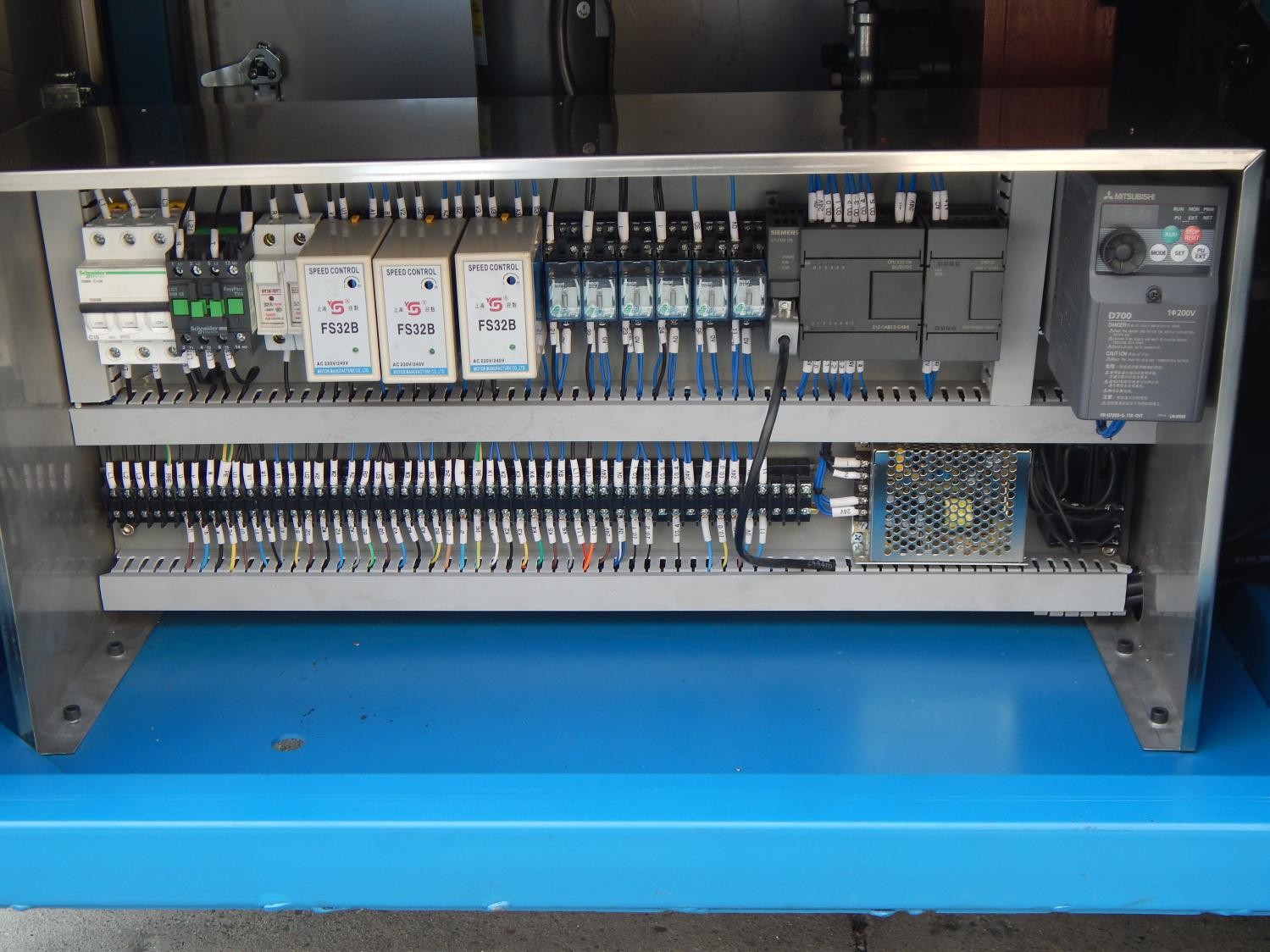

| speed control | Frequency control of motor speed |

| Voltage | 380v,50Hz |

| power | 1.5kw |

| net weight | 600kg |

olive oil filling and capping machine---features

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

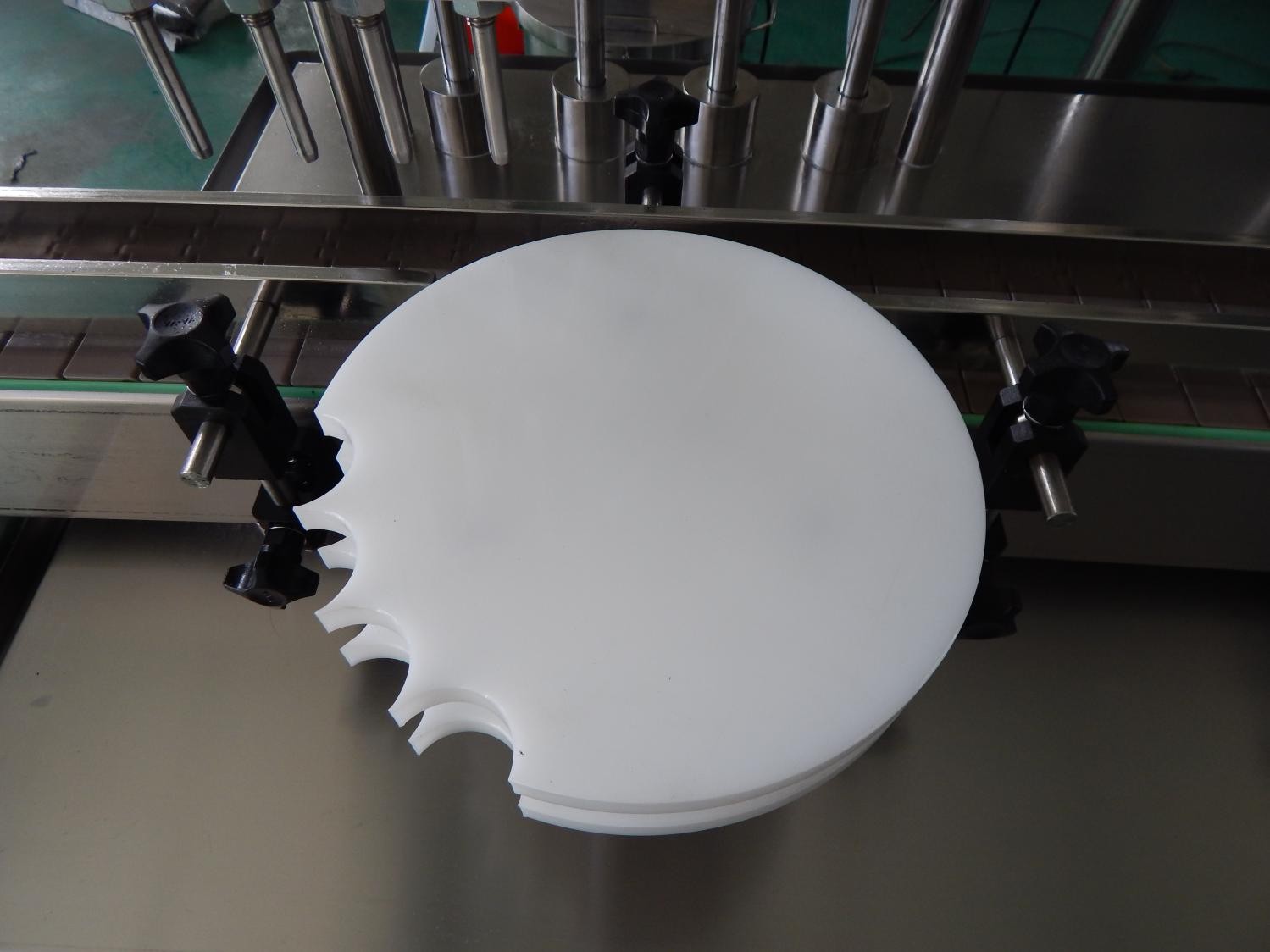

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5. Optional Siemens Touch screen/PLC

6.No bottle no filling/plugging/capping

1.automatic bottle feeding

2.automatic filling

3.automatic sort the inner plug

4.automatic hit the inner plug

5.automatic hanging cover part

6.Automatic three-knife capping

7.circuit control part

8.seperate bottle part