Semi-automatic weighing oil filling machine

- Price

- US $4160

- Model

- DFUSS-30

- MOQ

- 1 piece

Item specifics

- Name model:

- DFUSS-30

- Filling capacity

- 1-30KG

- Filling speed

- 130-240 barrels/hour

- Filling accuracy

- ±≤0.1%

- Power supply

- 380V

- Filling scale

- double scale

- Air pressure

- 0.4-0.7Mpa

- Equipment size

- 1250*860*1650

- Host weight

- about 200KG

Review

Description

1. Product description:

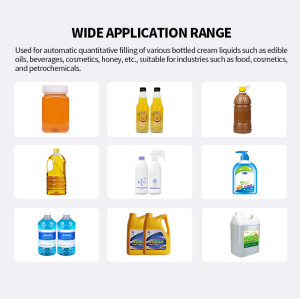

The filling machine is suitable for filling various oils and viscous liquids. Such as: lubricating oil, antifreeze, chemical raw materials, etc.

2. Technical parameters:

Name model: DFUSS-30

Filling capacity: 1-30KG (applicable bottle type 450*410*460, beyond which it can be customized separately)

Filling speed: 130-240 barrels/hour (calculated by 20L)

Filling accuracy: ±≤0.1%

Power supply: 380V

Filling scale: double scale

Air pressure: 0.4-0.7Mpa

Equipment size: 1250*860*1650

Host weight: about 200KG

3. Product features:

1. Using electronic sensing technology combined with single head, single pump and single frequency conversion technology, the filling accuracy is high and the speed is fast;

2. Using digital display and touch technology to guide the operation in Chinese throughout the process, which is more intuitive and easier to learn;

3. The weighing platform has no barrels and prohibits filling, differential pressure type zero-day collision barrel protection, automatic tare, automatic detection to start filling, intelligent foolproof, fault detection, etc., which can realize simultaneous filling and cap locking operations by a single person ;

4. The filling range is large, including roller weighing pan (for 5-30KG) and flat weighing pan (for 1-5KG). The system automatically detects barrel positioning and automatically starts filling; the height of the filling gun is adjustable, which can be fast Switch between barrels of different specifications;

5. The equipment is equipped with four-head (two large and small) double pumps, with one-key switching of net weight/gross weight and automatic/manual functions to further meet customer requirements for accuracy, speed, and low investment.

5.Features:

Equipped with large and small filling systems to ensure filling accuracy and efficiency: equipped with two groups of large and small filling systems, with a new filling head and variable frequency power system, to ensure that the fast and slow control of liquid materials during filling operations can be achieved in one go. The purpose of installation is accurate and fast.

Anti-drip design of the filling head to prevent dripping: the whole process is made, the inner plug of the filling head fits tightly with the filling head, and the bottom hole of the inner plug is equipped with a vacuum suction device to prevent material dripping from polluting the production environment and avoid waste of liquid materials .

Intelligent Chinese display, the operation status of the equipment is clear at a glance: full Chinese color LCD screen, full Chinese guidance operation, real-time display of operation status, weighing platform without bucket, overweight warning alarm.

The filling pipeline is easy to maintain, and the clamp joint is easy to disassemble: the pipeline is connected with a quick-release clamp joint, which can be easily disassembled, maintained and cleaned. The all stainless steel pipeline does not collapse, crack, age, and has a long service life. Greatly reduce equipment maintenance costs

Integrated drum and flat weighing pan, one machine with multiple functions, convenient and fast: equipped with integrated drum weighing pan and flat weighing pan, with large and small filling systems, it can be used for small and medium packaging under the condition of ensuring accuracy and speed. The purpose of occupying space and saving the user's cost.