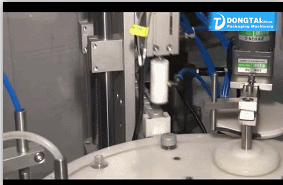

Cosmetics bottles 30ml essential oil filling and capping machine,small bottle filling machine

- Model

- KFY

Item specifics

- Material

- Stainless steel

- Application

- liquid

- Capacity

- 30-40 bottles/min

- Bottle type

- small bottles

- Powder

- 220V/380V

- Air pressure

- 0.6~0.8Mpa

- Delivery

- within 10 working days after order confirmed

- Warranty

- One Year

Review

Description

Characteristic:

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5.Simple structure, easy to operate and maintain magnetic moment screwing cap, the degree of tightness can be adjusted, no damage to cap.

6.No bottle no filling/plugging/capping

7.When small bottles filling capping machine has some troubles, the machine will stop automatically.

Main Technical Parameters:

Applied Bottle | 20-500 ml |

Productive Capacity | 10-50pcs/min 4filling nozzles 50-60pcs/min 6 filling nozzles 60-80pcs/min 8 filling nozzles 80-100pcs/min 10 fillling nozzles 100-120pcs/min 12 filling nozzles |

Filling Tolerance | 0-2% |

Qualified Stoppering | ≥99% |

Qualified cap putting | ≥99% |

Qualified capping | ≥99% |

Power Supply | 380V ,50HZ |

Power | 1.5KW |

Net Weight | 600KG |

Dimension | 2500(L)×1000(W)×1700(H)mm |

| 1.bottle unscrambler machine The disc (rotary)type unscramble bottle machine place the empty bottle orderly and then convey to the belt. |

| 2.Filling station It has the drop-proof device,high precision. The filling structure can customized according to the filling volume and different materials. |  |

| 3.Inner plug vibrator Inner plug vibrating disc send lots of inner plug orderly into the slide for manipulator access. |

| 4.Inner plug station Inner plug manipulator inhale the plug and press into the bottle accurately. |  |

| 5.Cap sorting vibrator The sorting cover vibrating disc settle the covers,send into the slide and then slip into the hang cover head. |

| 6.Hang cover station Bottles hanged covers when pass the hang cover head. |  |

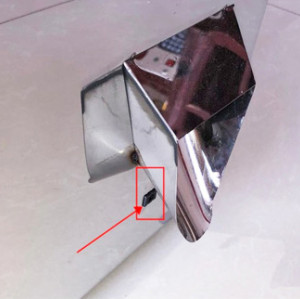

| 7.Press plug and Lock cover station After hang the covers, Press the plug down to the bottom by press plug hammer ,lock cover machine press the cap and bottle body into one though claw knives.The sealing structure can customized as the different kinds of covers, such as aluminium covers (common press cover)plastic covers(common screw cap) etc. |

We are a quality supplier of alibaba, a global well-known procurement and wholesale

platform. We have cooperated with alibaba for 9 years. If you do not have enough trust in

us, you can send us consultation through alibaba