automatic liquid filling machine,syrup filling machine,pharmaceutical syrup filling machine

- Model

- DGA-17

Item specifics

- Filling volume

- 20-100ml

- Speed

- 50-60ppm

- Filling accuracy

- ≥99%

- Air pressure

- 0.6-0.8Mpa

- Voltage

- 380v

- Power

- 7kw

- Weight

- 1000kg

- Size

- 5400*1800*1850mm

Review

Description

automatic liquid filling machine,syrup filling machine,pharmaceutical syrup filling machine

Product introduce:

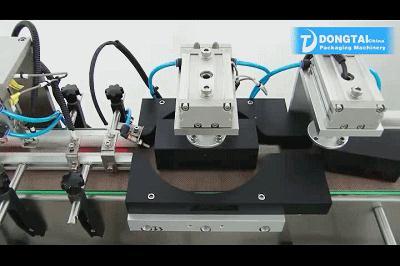

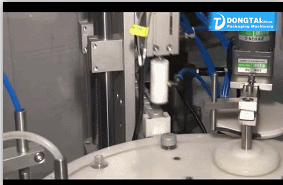

The equipment includes automatic bottle sorting system, double station filling and capping system and bottle collecting machine.

Click here to send a consultation to get a discounted price!

Product parameters:

Filling Volume | 20-100ml |

Speed | 50-60ppm |

Filling accuracy | 1% |

| power | 7kw |

| air pressure | 0.6-0.8Mpa |

| net weight | 1000kg |

| voltage | 380v |

| electric current | 28A |

Machine size | 5400L*1800W*1850H mm |

Click here to send a consultation to get a discounted price!

Product Advantages:

The machine is mainly composed of automatic bottle sorting, bottle measuring, automatic filling and automatic capping.

1. The touch screen can be used to control whether each station is opened, filling metering and modification of relevant parameters, machine alarm information and other functions.

2. Automatic bottle sorting function saves labor cost.

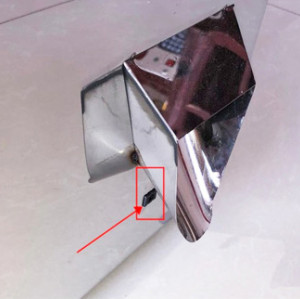

3. The bottle measuring function can detect the direction of the bottle mouth and whether the bottle is there or not. If the bottle is qualified, it will be followed by the station action. Non - conforming bottle or non - bottle follow-up station not moving.

4. The filling device adopts the servo motor to push the material, and the filling can be completed by modifying the filling quantity parameters in the touch screen.

5. The cover is removed by air bag and the cover is removed by servo motor. The airbag prevents the cover surface from scratching, while the torque control mode of the servo motor makes the torque of the cover controllable within a certain range.

automatic bottle sorting |

automatic bottle measuring |

automatic filling |

automatic capping |

Finished product Display

Click here to send a consultation to get a discounted price!

We appreciate your reading and hope you have a good day.

If there is any doubt or interested in our product, please be FREE to contact with us or send your enquiry.

I look forward to hearing from you soon!

Thanks a lot.