Automatic Oral Liquid Pharmaceutical Plastic Ampoule Bottling Blow-fill-seal Machine

- Model

- DTFS-4

Item specifics

- Model

- DTFS-4

- Max. Forming Depth

- 12mm

- Cutting Speed

- 0-25 times

- Packing Material

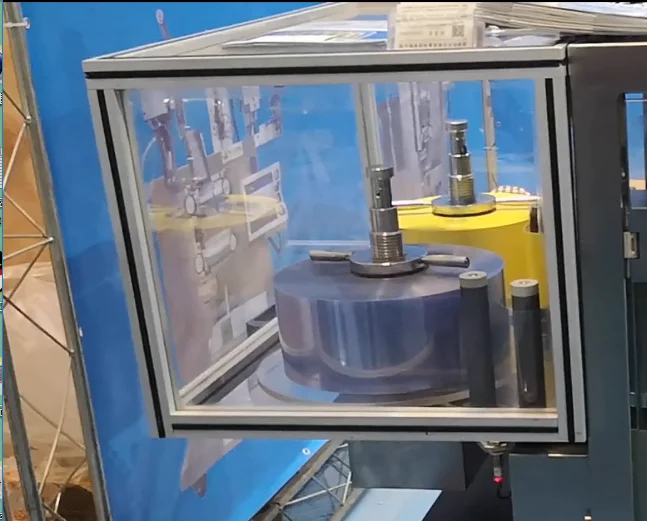

- PVC/PET combined sheet (thickness:0.2-0.4mm)

- Filling Volume

- 1-50ml

- Power Supply

- 220V/380V 50HZ (can be customized)

- Machine Weight

- 850kg

- Machine Dimension

- 2300*850*1450mm

Review

Description

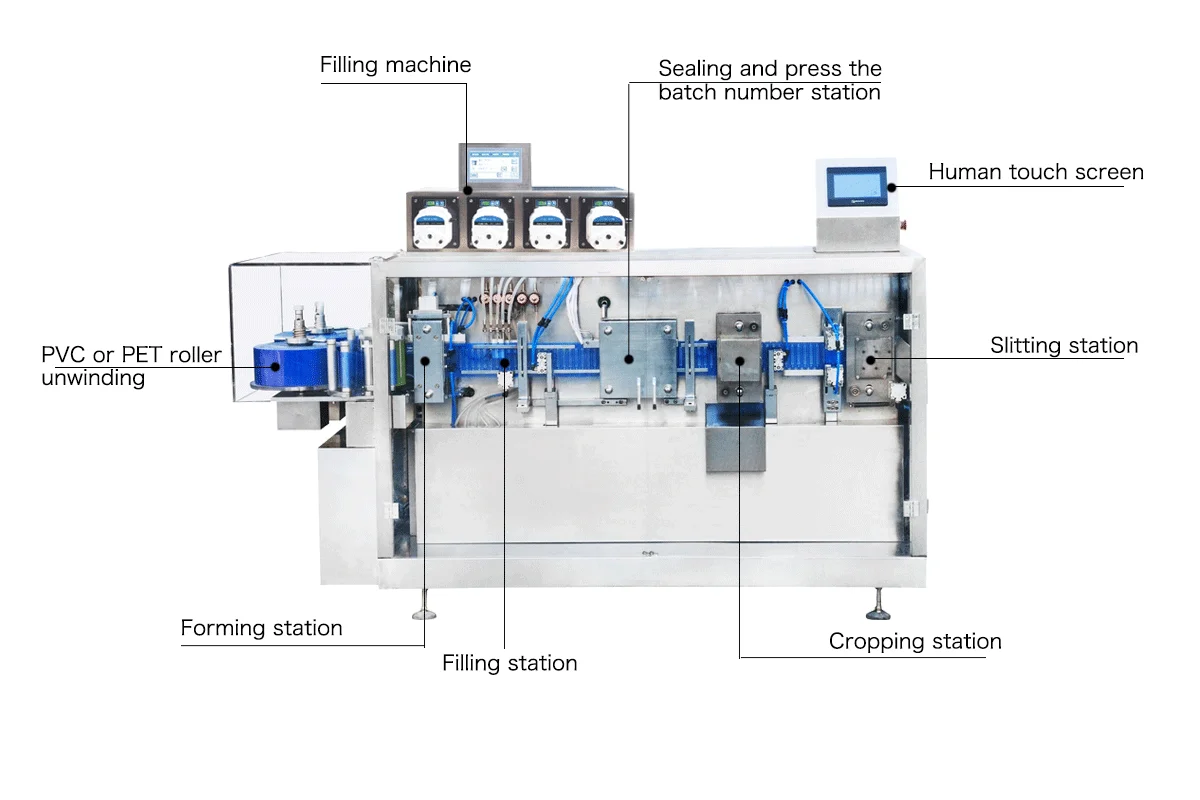

Product Name: Automatic Oral Liquid Pharmaceutical Plastic Ampoule Bottling Blow-fill-seal Machine

Model: DTFS-4 ampoules forming filling sealing machine

This machine is a kind of compact type liquid filling and sealing machine, it is suitable for small batch filling for different product and widely used for filling oral liquid, perfume, liquid , essential oil, olive oil, health care product etc in pharmaceutical, herbal, pesticide, cosmetic, food and supplement area.

Video Show: https://youtu.be/kilaKPvyfT0

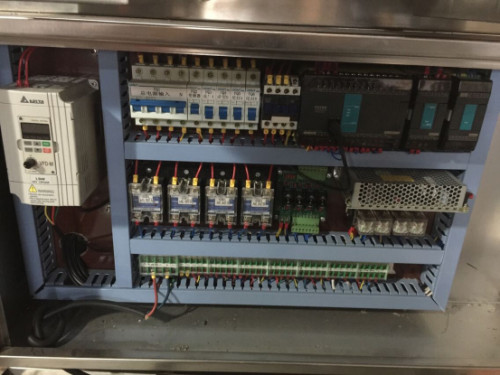

1.PLC control,Stepless frequency control

2.Roll-off, plastic forming, filling, lot marking, indentation, tail cutting, cutting and other seven steps are automatically completed by the program

3.The Man-machine interface for the user uconvenience and easiest operation.

4.The filling head doesn't leak, foam or spill.

5.The relevant parts in contact with the liquid are all made of high quality stainless steel and meet GMP standards.

6.Main pneumatic components are import fittins.

7.Electronic peristaltic pump automatic filling system and filling machine are accurate to measure, and error is small.