PLC controlled 30ml bottle filling machine,automatic liner filling machine

- Model

- DGA-17

Item specifics

- Filling volume

- 20-100ml

- Speed

- 50-60ppm

- Filling accuracy

- ≥99%

- Air pressure

- 0.6-0.8Mpa

- Voltage

- 380v

- Power

- 7kw

- Weight

- 1000kg

- Size

- 5400*1800*1850mm

Review

Description

PLC controlled 30ml bottle filling machine,automatic liner filling machine

Samples:

Brief Introduction:

Automatic filling and capping machine

The machine is mainly composed of automatic bottle handling, bottle measuring, automatic

filling and automatic capping. Through the touch screen, it can control whether each

station is open, filling metering and modification of related parameters, machine alarm

information prompting and other functions. The automatic bottle handling feature saves

labor costs. The bottle measuring function detects the direction of the bottle mouth and the

bottle, and the qualified bottle moves in the subsequent station. Unqualified or unfilled

follow-up station does not work.

Here is Liquid filling machine,If you want dry syrup Powder Filling machine,we

have both,please give us your valuable inquiry,we will reply you soon.

Technical parameters:

Filling Volume | 20-100ml |

Speed | 50-60ppm |

| power | 7kw |

| air pressure | 0.6-0.8Mpa |

| net weight | 1000kg |

| voltage | 380v |

| electric current | 28A |

Machine size | 5400L*1800W*1850H mm |

Product Advantages:

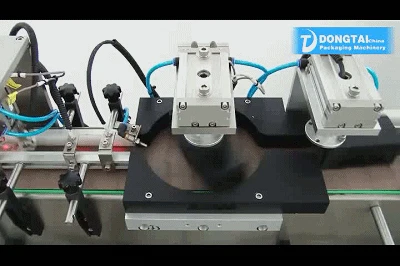

The machine is mainly composed of automatic bottle handling, bottle measuring, automatic

filling and automatic capping.

1. Through the touch screen, it can control whether each station is open, the filling

metering and modification of related parameters, and the machine alarm information prompt.

2, automatic bottle handling function saves labor costs.

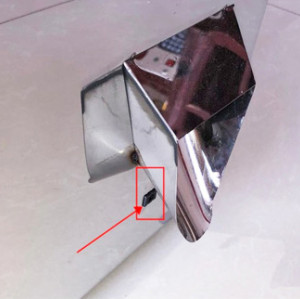

3. The bottle measuring function detects the direction of the bottle mouth and the bottle,

and the qualified bottle moves in the subsequent station. Unqualified bottles or no bottles

follow-up stations do not work.

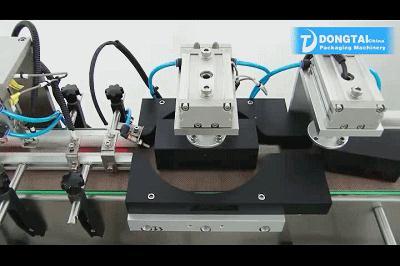

4. The filling device adopts the servo motor pushing method, and the filling correction

can be completed by simply modifying the filling amount parameter in the touch screen.

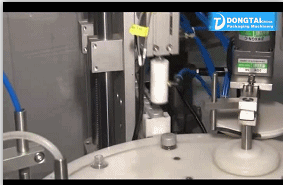

5. The screw cap adopts the method of taking the airbag to take off the cover and the

servo motor to screw the cover. The airbag prevents the surface of the cover from being

scratched, and the torque control mode of the servo motor enables the torsion of the cap

to be controlled within a certain range.

|  |

| automatic bottle sorting | automatic bottle measuring |

|  |

| automatic filling | automatic capping |

Warming welcome your inquiry for our liquid filling capping machine~!

Q: How long will take for the delivery of product?

A: 7 days for standard model, if machine in stock, will delivery immediately, customized

model depend on customer requirements, usually about 30 days.

Q: What’s the insurance of after-sale service after purchase?

A: All our products, will be totally tested by QC department before delivery, with strict

quality control process. The product is cost-effective during use, stable and reliable.

One year warranty service for all machine, please feel free to contact us if you have any questions.

Q: When the machine arrives at the work site, is it easy to install? How to solve

the problem of quick installation and use?

A: All machine model with installation video, to show the installation process

more intuitively, and we will provide remote video technical support to solve your doubts

and ensure that your installation is correct.

Install video URL: https://www.facebook.com/groups/1644623782523083/

https://www.youtube.com/channel/UC_wUu5QTxgZsfGRzgxxK29w?view_as=subscriber

(FOLLOW US ON YOUTUBE, TO SEE MORE ABOUT US)

After-sales appointment installation service phone :

+8618560751875 86-531-88168830 engineer Zhang

Q: During the use of the machine, how to get after-sale service?

A: We have professional foreign installation and commissioning engineers, which have

many years of experience in foreign debugging with deeply recognized by customers. We

will provide on-site installation and commissioning services for foreign customers, and we

will guide your workers directly.

Q: Will the accessories change frequently with machine ?

A: The service life of the accessories is related to the daily maintenance. When ordering,

we will give you free wearing parts and provide you with daily maintenance strategies.