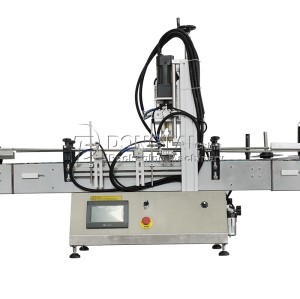

DT-16 Automatic anti-corrosion liquid filling machine

- Model

- DT-16

Item specifics

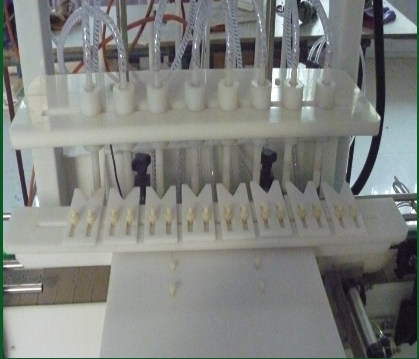

- Filling head

- 6-12

- Production capacity

- 1000-3500 bottles/hour

- Filling capacity

- ±1%

- Filling volume

- 20-1000Ml

- Air pressure

- 0.4-0.6Mpa

- Power

- 500kw

Review

Description

DT-16 Automatic anti-corrosion liquid filling machine

Product introduce:

Anti-corrosive filling machine is specially developed for filling corrosive liquids and

cosmetics which can not touch metal liquids. PP (polypropylene) material is used in the

main body of the equipment, and PTFE material is used in the liquid passage part. The

exposed metal parts (such as cylinders, motors, etc.) are all protected and treated. They

are placed in the PP plastic box to prevent the corrosive gas damage caused by volatile

flying, so as to ensure the long-term use of the equipment. The equipment is controlled by

Taida PLC and color touch screen. It has stable performance, friendly operation interface

and clear parameter setting. Electrical appliances adopt the French Schneider brand, and

the pneumatic part adopts the Taiwanese Yadeke brand, so as to ensure the long-term

stable operation of the equipment.

Technical parameter:

| Filling head | 6-12 |

| Applicable bottle height | 100-350mm |

| Applicable bottle diameter | 16-50mm |

| Production capacity | 40 bottles/min |

| Filling accuracy | 1% |

| Filling volume | 20-1000ml |

| Size | 2000mmX910mmX2200mm |

Features:

1. Linear design, suitable for all types of bottles (including special-shaped bottles).

2. Easy adjustment, no bottle filling, accurate filling quantity and counting function.

3. The equipment has a positioning system and a liquid level control system to ensure the

accurate positioning of the bottle mouth.

4. The equipment adopts anti-corrosion and anti-drip filling head to ensure no drip leakage

and no wire drawing after closing the filling head, which is the leading technology in the country.

Details show: