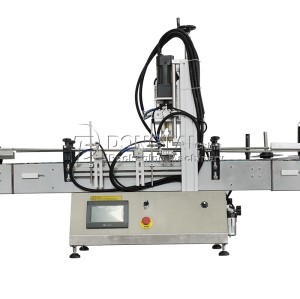

soy sauce filling machine/leaf fertilizer/vinegar filling machine

Review

Description

soy sauce filling machine/leaf fertilizer/vinegar filling machine

soy sauce filling machine---Product introduce

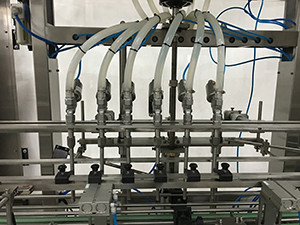

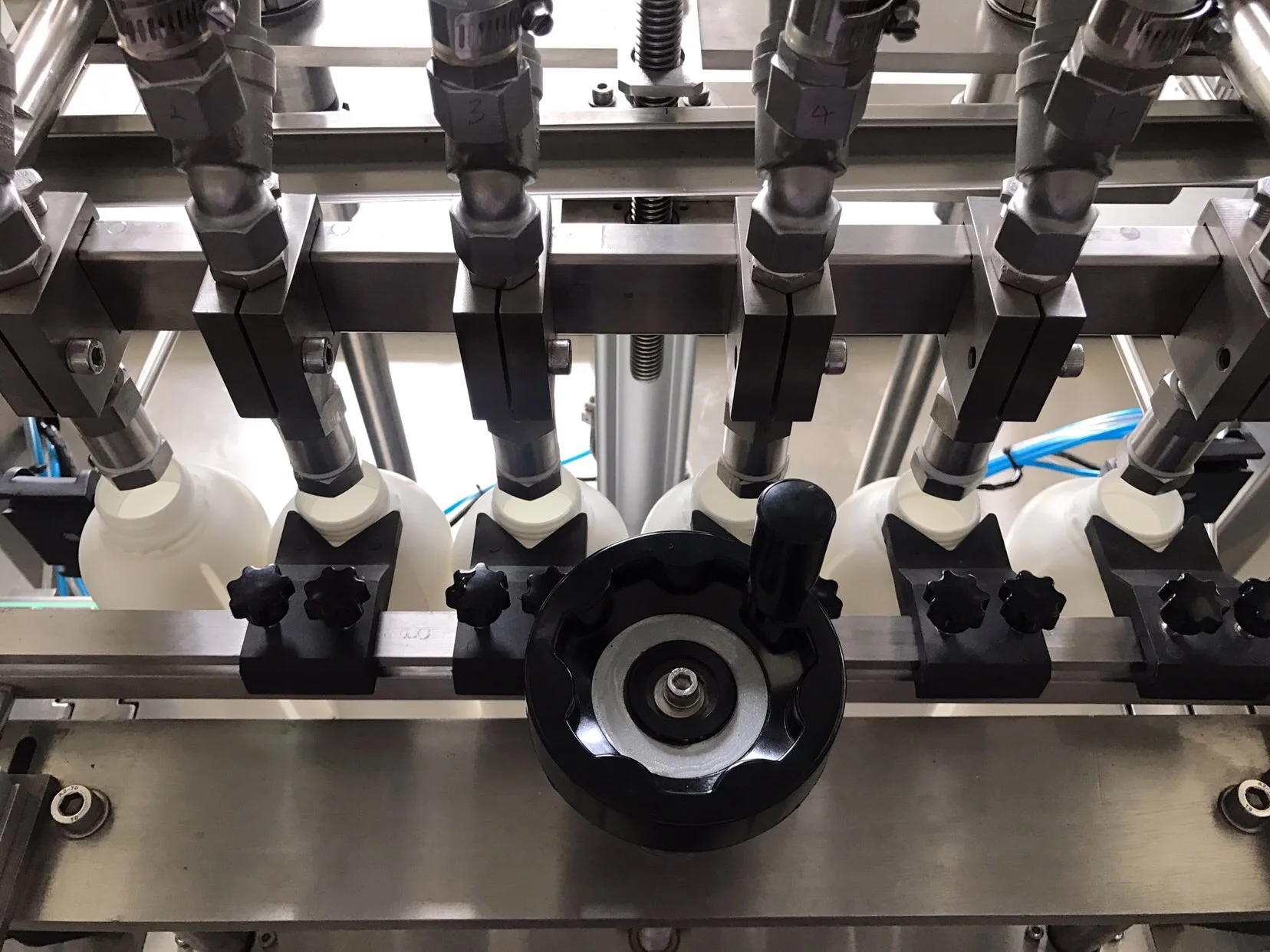

Self Flowing Type Liquid Filling Machine is a kind of straight line self-flowing filling machine, and achieves different measuring through controlling the time. It features exquisite design, simple structure, and it doesn't to require replacing any part for filling different shapes and sizes of containers. The parts contacting with materials are made of stainless steel and anti-corrosive materials. The machine features high efficiency, accurate filling, convenient adjustment and operation, long life, cost effective and practical, no leakage and strong adaptability etc. It is widely used for filling various kinds of flowing liquid such as foods & beverage, medicine, chemicals, pesticide, oil products and cosmetics etc.

leaf fertilizer filling machine---Product features

1.This machine is suitable for filling containers with different specifications, and can switch specifications in a few minutes.

2.The filling period is short and the production capacity is high.

3.The replacement filling specification does not need to add the spare parts, only need to make the adjustment to complete.

4.Users can choose filling quantity according to their own production capacity to determine the filling head number.

5.Touch-type operation color screen, can display production status, operation procedures, filling methods and so on. The screen is intuitive, easy to operate and easy to maintain.

6.According to the material, the user can choose the explosion-proof and corrosion-proof type.

vinegar filling machine---Technical parameter

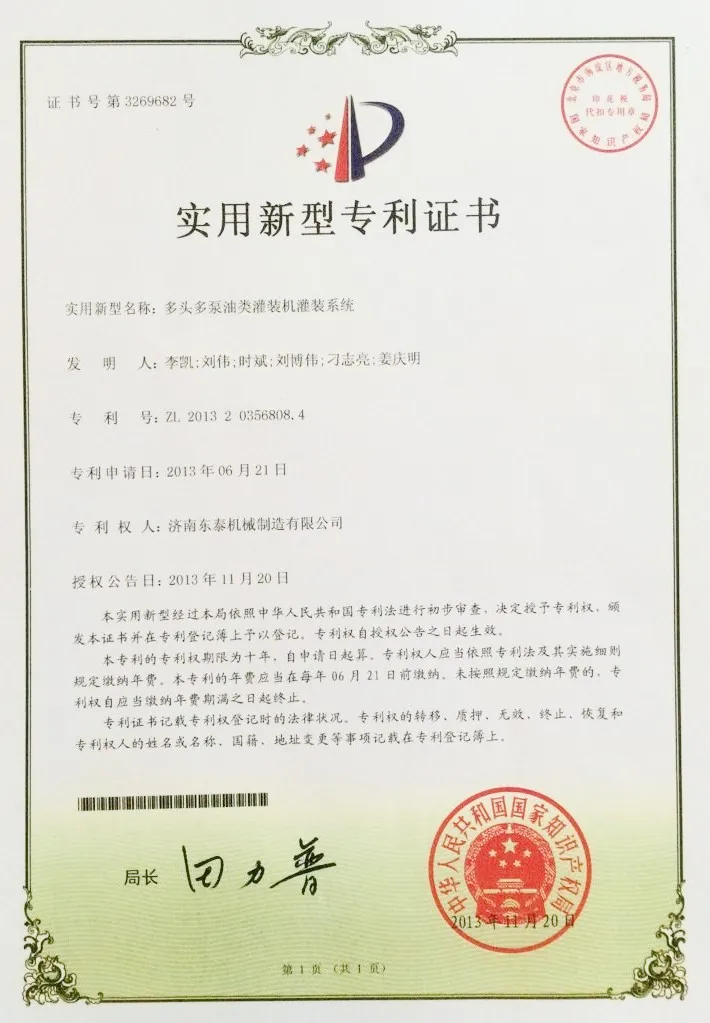

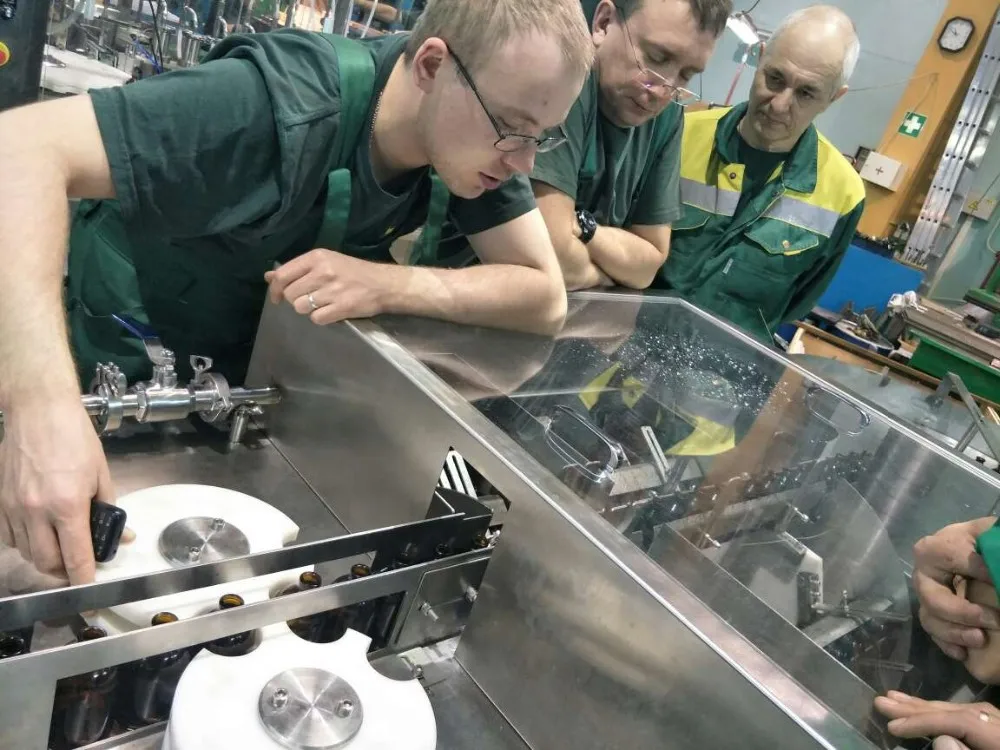

Iorder to ensure product quality, all suppliers of raw materials, electrical components, and industrial automation that strictly control all aspects of circulation are from well-known brands at home and abroad. They must be strictly inspected by quality inspectors before entering the warehouse. Use, product production is completed, from the assembly plant into the commissioning workshop, after a number of rounds of precision and speed test, after commissioning can be allowed to leave the factory.

1. Technical support online service provided.

2. Technical files service provided.

3. On-site training service provided.

4. Spare parts replacement and repair service provided.