SF-II Magnetic pump liquid filling machine

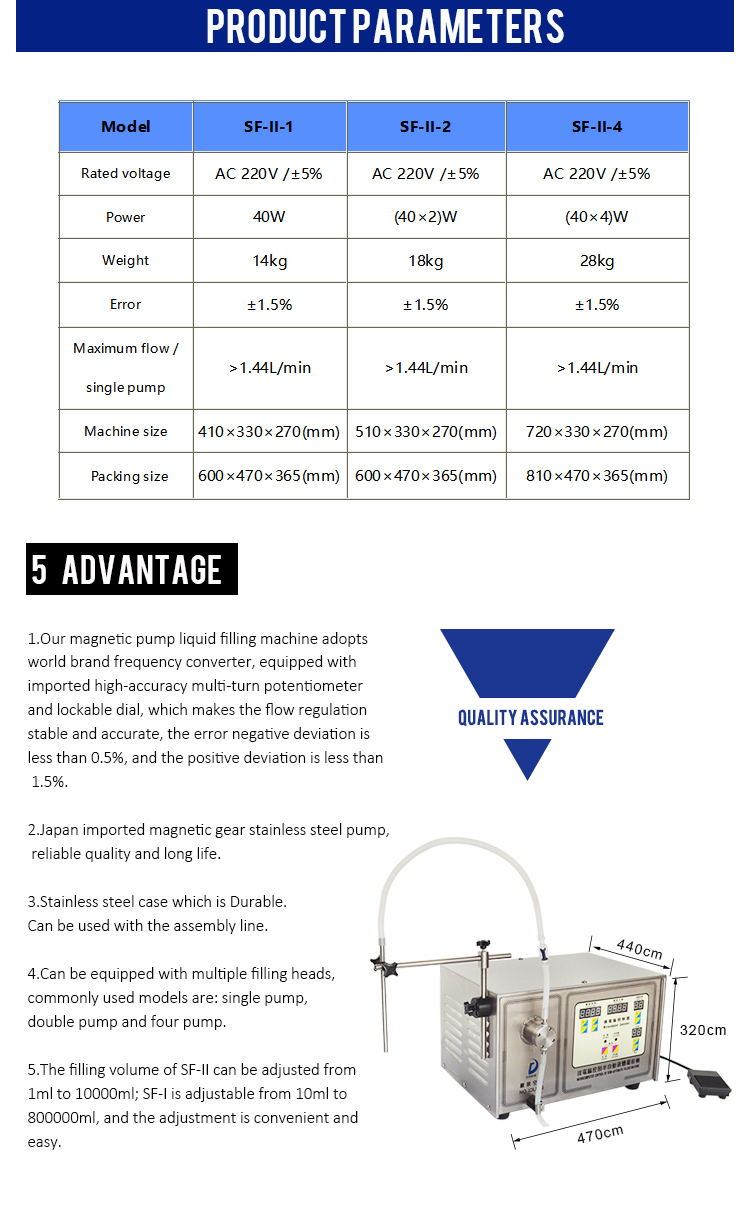

- Model

- SF-II

Item specifics

- Voltage

- AC 220V /±5%

- Power

- 40w

- Weight

- 14kg

- Error

- ±1.5%

- Size

- 410×330×270(mm)

- Large flow / single pump

- >1.44升/分

Review

Description

SF-II Magnetic pump liquid filling machine

Product introduce:

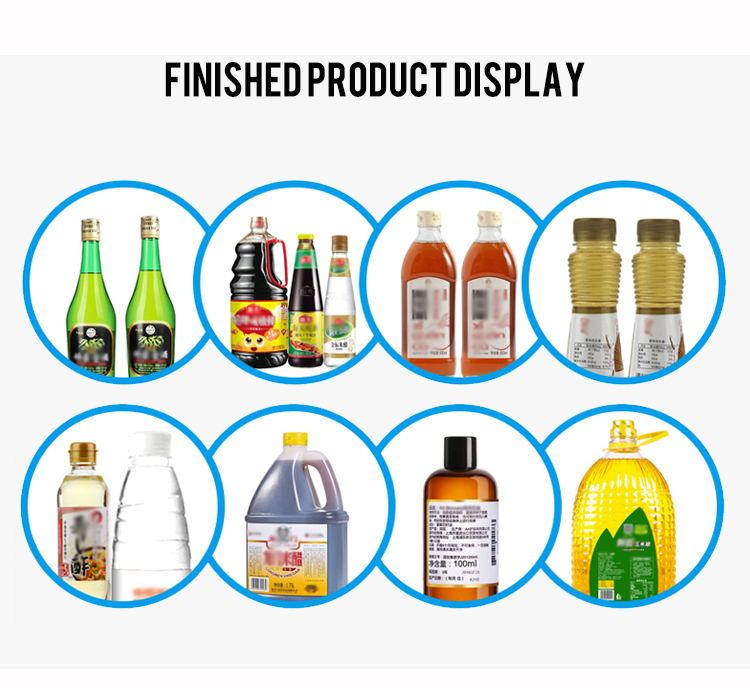

The magnetic pump liquid filling machine, also known as the small magnetic pump filling

machine, can fill a large type of liquid, including highly viscous liquids. Such as: a variety

of pharmaceuticals, chemicals, oils, cosmetics, food and other non-particulate liquid; high

filling accuracy, suitable for laboratory use.

Principle and characteristics of magnetic pump filling machine:

1 This magnetic pump filling machine is a best-selling product in liquid filling machine. It

adopts world brand frequency converter, imported high-precision multi-turn potentiometer

and lockable dial, which makes the flow regulation stable and accurate, and the error is

negative. Less than 0.5%, positive deviation is less than 1.5%.

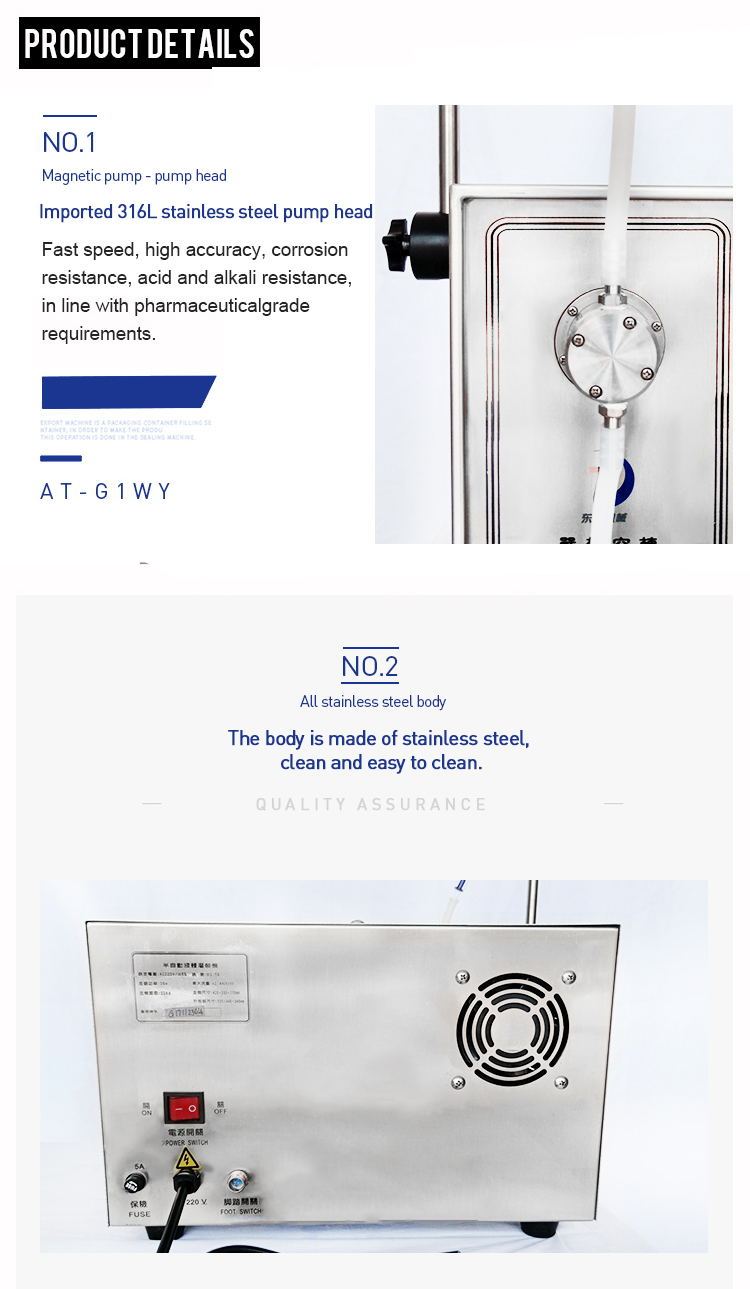

2 Japan imported magnetic gear stainless steel pump, reliable quality and long life;

3 stainless steel chassis, durable;

4 small in size and easy to operate;

5 cleaning and cleaning is convenient;

6 Full-featured, automatic manual. Can be used with the assembly line;

7 can be equipped with multiple filling heads, commonly used models are: single pump,

double pump and four pump;

8 Filling amount SF-II can be adjusted from 1ml to 10000ml; SF-I can be adjusted from

10ml to 80,000ml, which is convenient to adjust.

Magnetic pump liquid filling machine use precautions:

1.Check the magnetic pump liquid power supply voltage 220 (±5%) frequency, 50Hz/60Hz

(±5%) AC power supply, correctly use the customer-defined fuse, the power cord must be

removed before installing the fuse;

2.To avoid personal injury, please use the local AC power socket, the power plug should

be in good contact. Otherwise it is easy to damage the filling machine;

3.The liquid filling machine should be placed in a place with low ventilation and dryness,

and the distance between the horizontal placement and the wall or other objects should be

greater than 20CM to ensure normal ventilation;

4.check valve must be vertically downward, otherwise it will affect the accuracy;

5.The magnetic pump filling machine must be vertically downward, otherwise there will be

dripping phenomenon;

6.The bending angle of the pipeline is not suitable for small people, which affects the flow

and accuracy of the filling of the magnetic pump filling machine;

7.The level of the raw material tank should not be too different, otherwise it will affect the

accuracy of the magnetic pump liquid filling machine;

8.Volatile liquids should be used in a circulating air environment