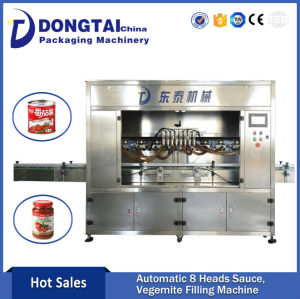

TSF-2 Automatic two-head sauce filling machine

- Model

- TSF-2

Item specifics

- Packing speed

- 1200-1500 bottles/hour

- Packing accuracy

- <2g( Depending on the nature of the material)

- Current

- 3A

- Voltage

- 220V/110V 50/60HZ

- Power

- 500w

- Air pressure

- 0.5-0.7MPA

- Size

- 2000*800*1700mm

Review

Description

TSF-2 Automatic two-head sauce filling machine

Product introduce:

This series of filling machine adopts the pneumatic principle of piston cylinder, which is

suitable for mushroom sauce with seasoning and concentration, chili sauce, bean paste,

peanut butter, sesame paste, jam, butter hot pot bottom material, red oil hot pot bottom

material. Wait for the filling of more viscous sauces. The filling rotary valve can be

customized with customer materials to meet the filling requirements of different customer

materials. Equipped with a horizontal mixing hopper to ensure maximum material uniformity

during the filling process, no oil sauce separation, to ensure the accuracy of filling each

bottle, the equipment is designed to greatly shorten the filling of the hopper to the filling

head The distance overcomes the disadvantages of some oils with large oil content (such

as: chili oil containing sesame seeds) in the filling process, and some of the bottled sauces

have a large filling error.

Technical parameter:

| Packing speed | 1200-1500 bottles/hour |

| Packing accuracy | <2g( Depending on the nature of the material) |

| Current | 3A |

| Voltage | 220V/110V 50/60HZ |

| Power | 500w |

| Air pressure | 0.5-0.7MPA |

| Size | 2000*800*1700mm |

Features:

1. Filling machine is based on the improvement of similar products on the basis of foreign

similar products, special filling sauce filling head, vacuum sucking anti-drip and mechanical

anti-drip double anti-drip protection, will not pollute the bottle mouth during filling process

Or the bottle body for easy subsequent capping and labeling.

2. The filling machine adopts the method of horizontal pushing, which greatly shortens the

distance from the lower hopper to the filling head, improves the filling speed, and more

importantly solves some bottles which appear in the filling process of materials with large

oil content. There are many oils and some filling problems with more bottles of sauce,

which greatly improves the filling accuracy.

3. The product is simpler and more convenient in terms of operation, precision error

installation adjustment, equipment cleaning, maintenance and so on.

4. The machine is compact and reasonable in design, simple and beautiful in appearance

and convenient in filling volume adjustment.

5. The machine is driven by two filling heads, which are driven by two cylinders, and the

filling material is faster and more precise.

6. The pneumatic components of Germany FESTO, Taiwan AirTac and the electronic

control components of Taiwan Delta are used for stable performance.

7. The material contact part is made of SUS316 stainless steel material. The patent

SUS316 stainless steel enlarges the rotary valve 40*60 aperture to ensure the filling of

large granular materials. It has wide applicability. One machine can fill a variety of

materials, which greatly saves purchase cost.

8. Filling machine adopts Korean optical eye device, Taiwan PLC touch screen, frequency

converter and French electrical components.

9. Easy adjustment, no bottle filling, accurate filling and counting function.