Automatic Bottle Liquid Shampoo Filling Machine,Detergent Filler

- Model

- DT-16H

Item specifics

- Capacity

- 7200 b/h(100m)

- volume

- 50-1000ml

- precision

- ±1%

- bottle diameter

- 40-100mm

- bottle height

- 60-300mm

- air pressure

- 0.6-0.8Mpa

- total power

- 1.5kw

- voltage

- AC220V,50/60Hz

- net weight

- 750kg

- dimension

- 2000(L×1030(W)×2300(H)mm

Review

Description

Automatic Bottle Liquid Shampoo Filling Machine,Detergent Filler

Brief introduction of the products:

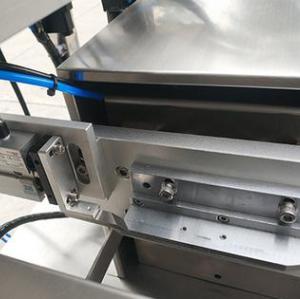

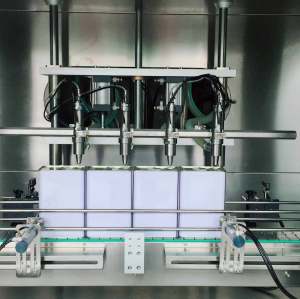

The machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action. It could dive with non-foam,with accurate measurement, simple structure,convenient operation and fast production speed. Suit for all kinds of bottle shape for water aqua such as: wine, vinegar, fine chemicals, pesticide, daily chemical products. Play a beautiful, dustproof, protective role

Product features:

1.This machine is suitable for filling containers with different specifications, and can switch specifications in a few minutes.

2.The filling period is short and the production capacity is high.

3.The replacement filling specification does not need to add the spare parts, only need to make the adjustment to complete.

4.Users can choose filling quantity according to their own production capacity to determine the filling head number.

5.Touch-type operation color screen, can display production status, operation procedures, filling methods and so on. The screen is intuitive, easy to operate and easy to maintain.

6.According to the material, the user can choose the explosion-proof and corrosion-proof type.

2.The filling period is short and the production capacity is high.

3.The replacement filling specification does not need to add the spare parts, only need to make the adjustment to complete.

4.Users can choose filling quantity according to their own production capacity to determine the filling head number.

5.Touch-type operation color screen, can display production status, operation procedures, filling methods and so on. The screen is intuitive, easy to operate and easy to maintain.

6.According to the material, the user can choose the explosion-proof and corrosion-proof type.

Technical parameter:

| Capacity | 7200 b/h(100m) |

| volume | 50-1000ml |

| precision | ±1% |

| bottle diameter | 40-100mm |

| bottle height | 60-300mm |

| air pressure | 0.6-0.8Mpa |

| total power | 1.5kw |

| voltage | AC220V,50/60Hz |

| net weight | 750kg |

| dimension | 2000(L×1030(W)×2300(H)mm |