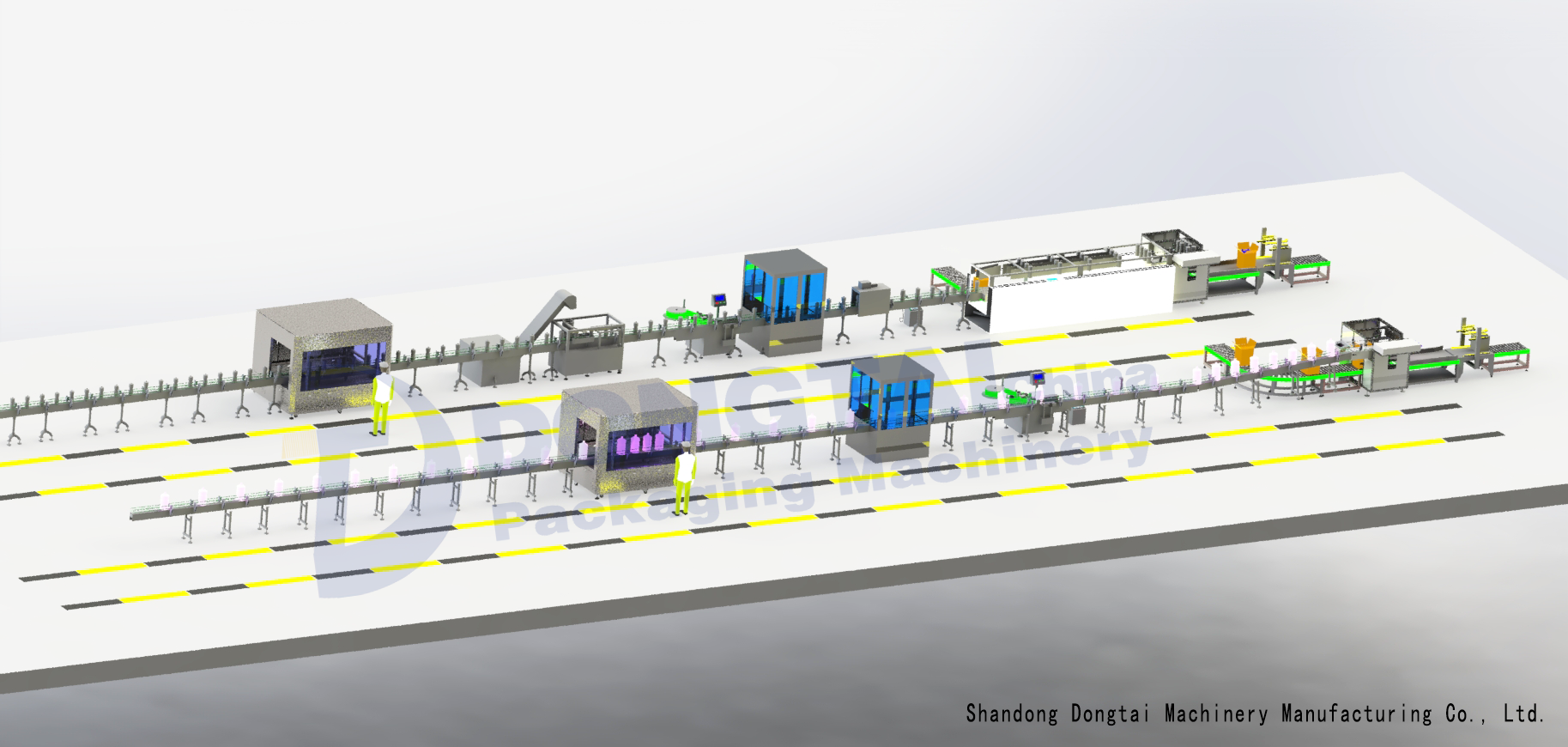

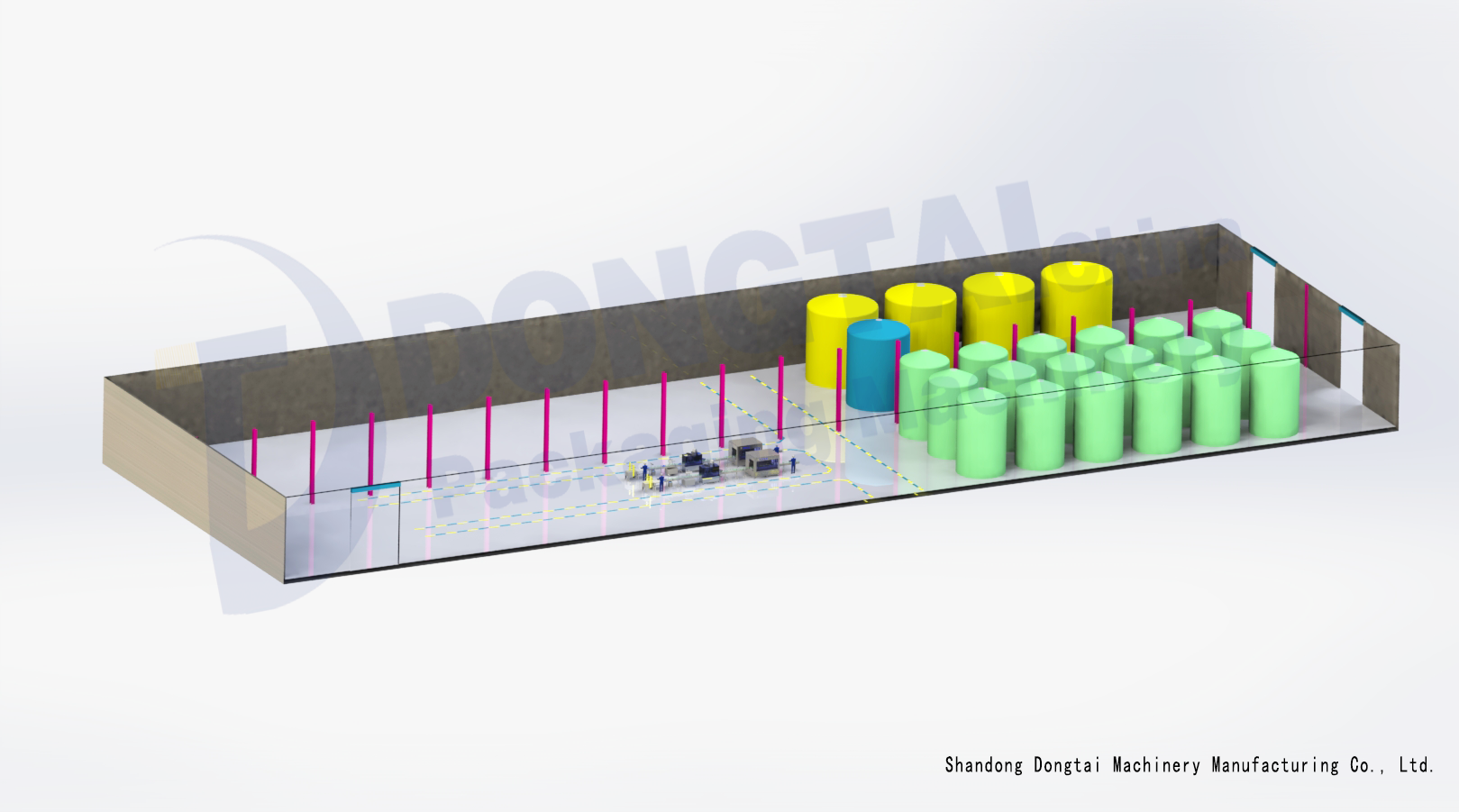

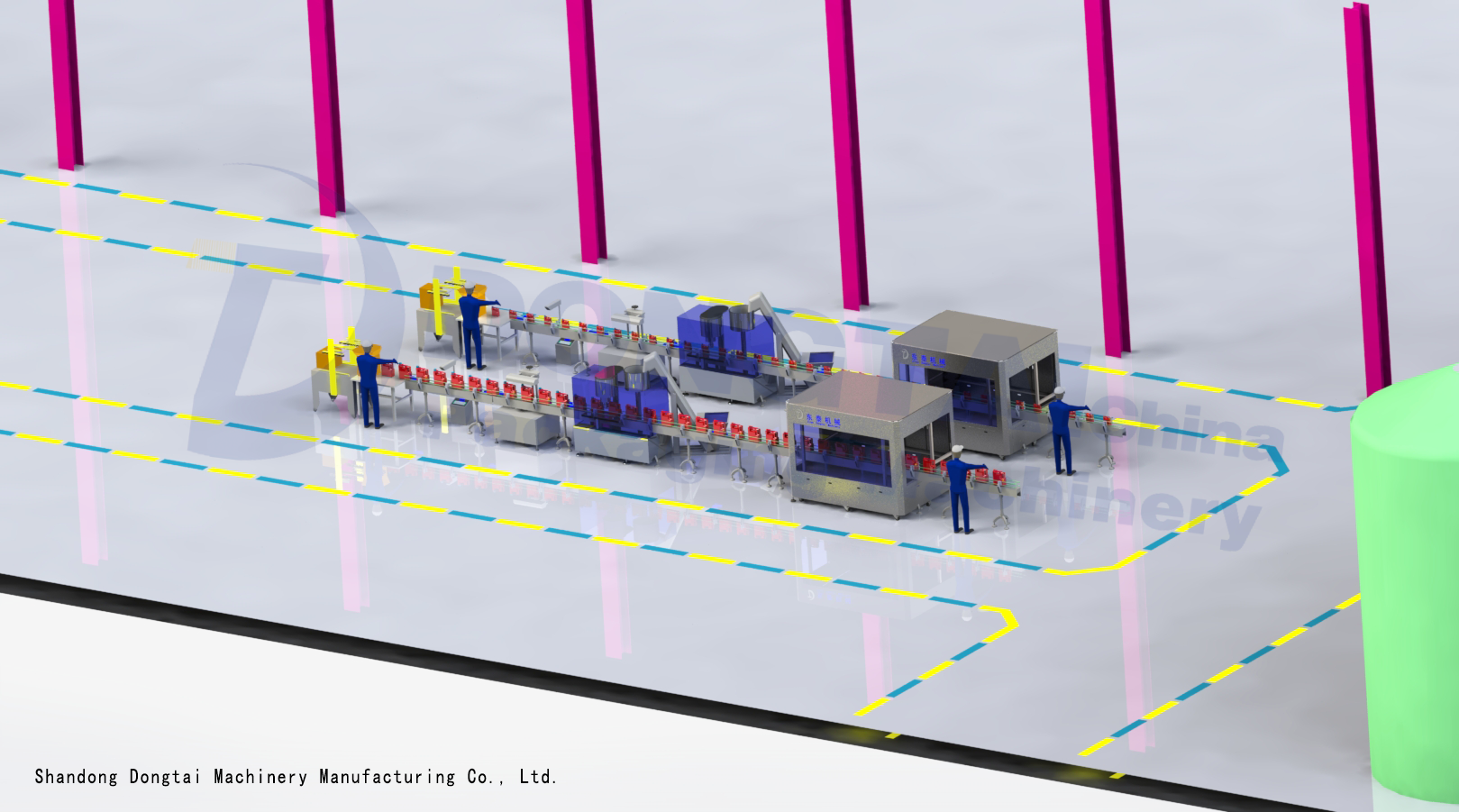

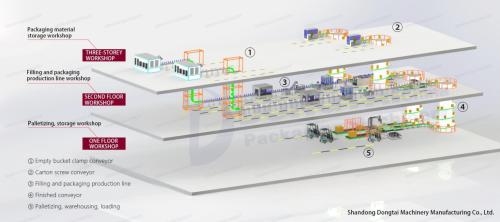

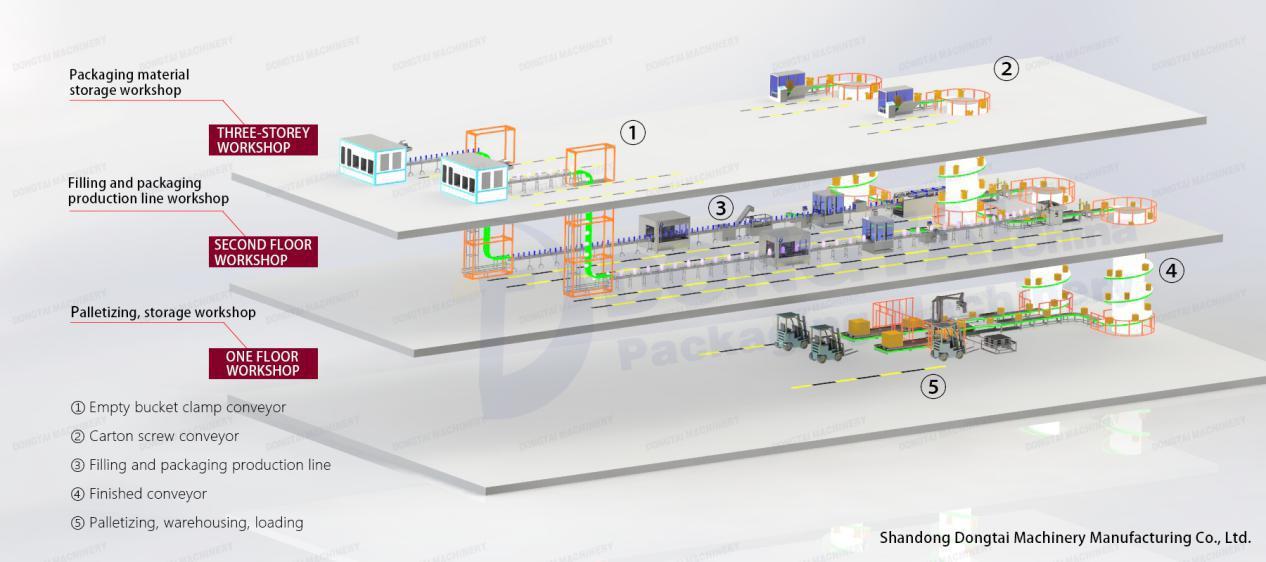

Automatic Lubricants Bottle Filling and packaging Line

- Model

- FPML

Item specifics

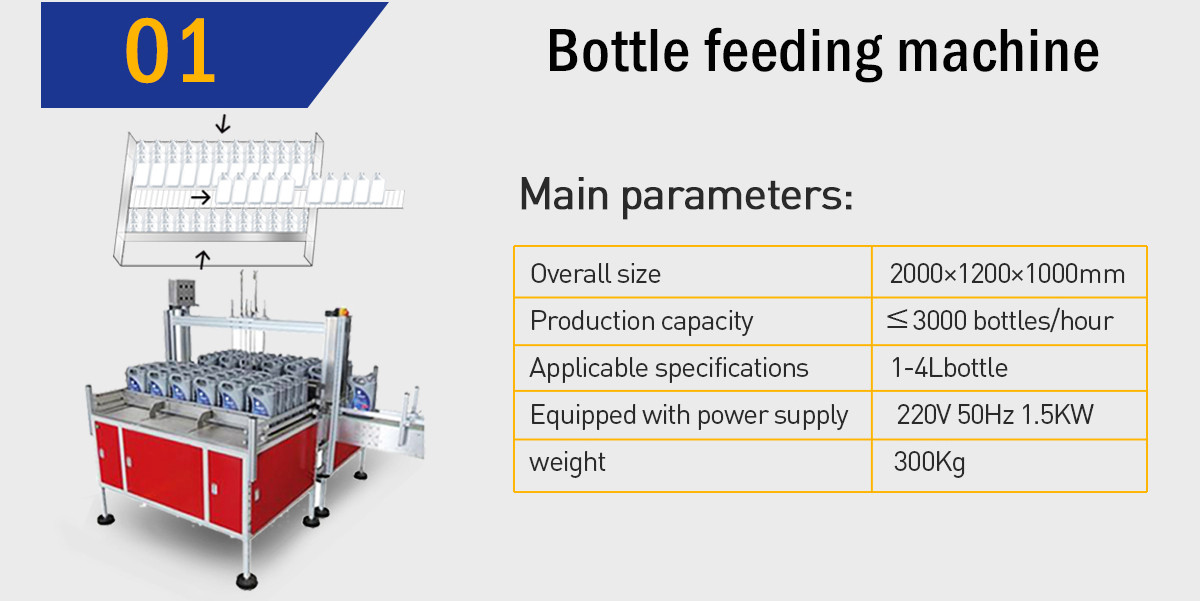

- Filling nozzles

- 8

- Filling speed

- 1500-2000 (barrels / hour)

- Filling capacity

- 1-5L

- Filling accuracy

- ± ≤ 0.1% FS

- Whole line consumption

- about 100L\Min

- The equipment noise

- less than 50D

Review

Description

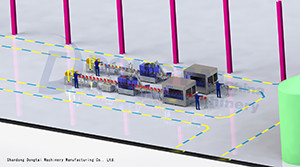

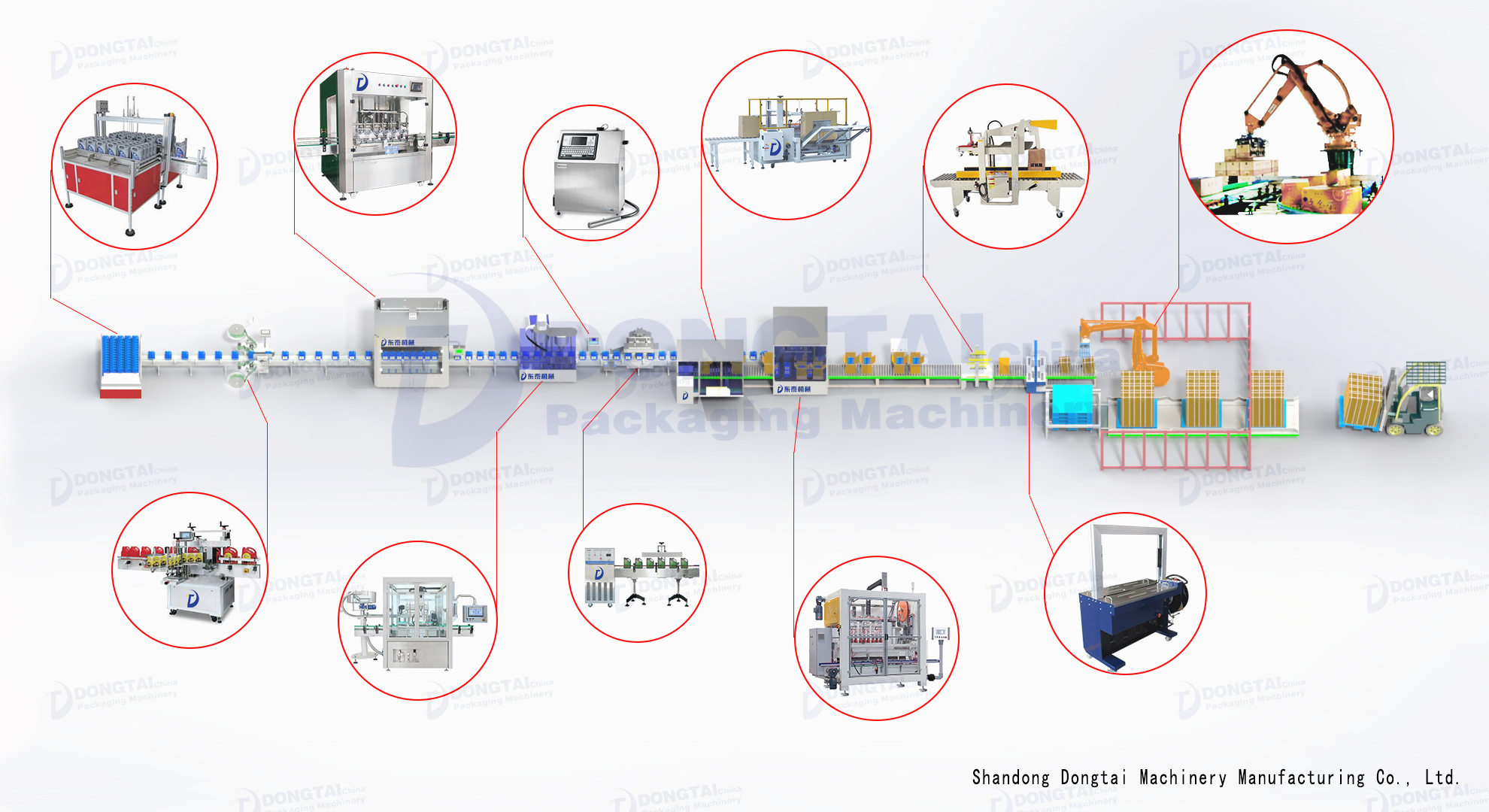

The filling line equipment has the characteristics of stable, easy operation, high cost performance and high automation. Compared with the same kind of product, it has a longer service life, a complete set of ability, and a reasonable design of the whole line. Equipped with coordinated photoelectric and whole line interlocking devices, the whole line needs only 2-4 workers for operating. The technology used is the leading level in today's industry. The whole line of filling equipment meets the needs of production, unmanned and integrated production.

Filling line specifications |

|

Filling nozzles |

8 |

Filling speed |

1500-2000 (barrels / hour) |

Filling capacity | 1-5L |

Filling accuracy | ± ≤ 0.1% FS |

Power Supply | 220/380V3 phase +Earth Wire, 50 Hz |

Number of workers | 3-5 people |

Whole line consumption | about 100L\Min |

The equipment noise | less than 50D |

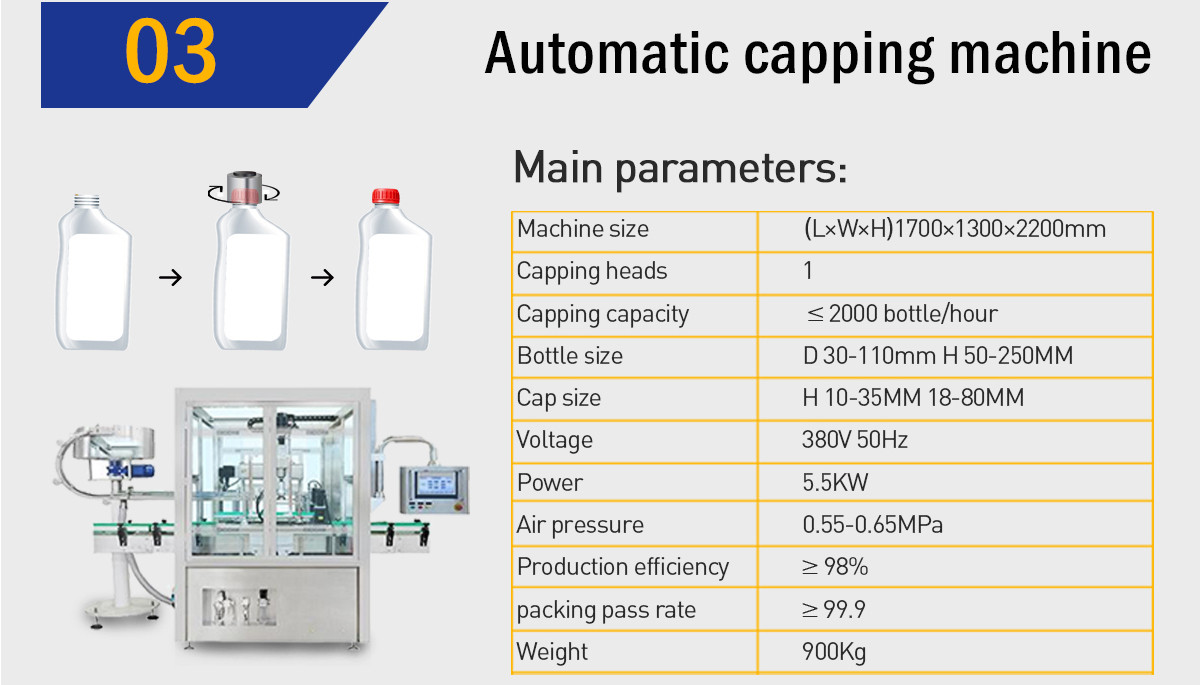

Features:

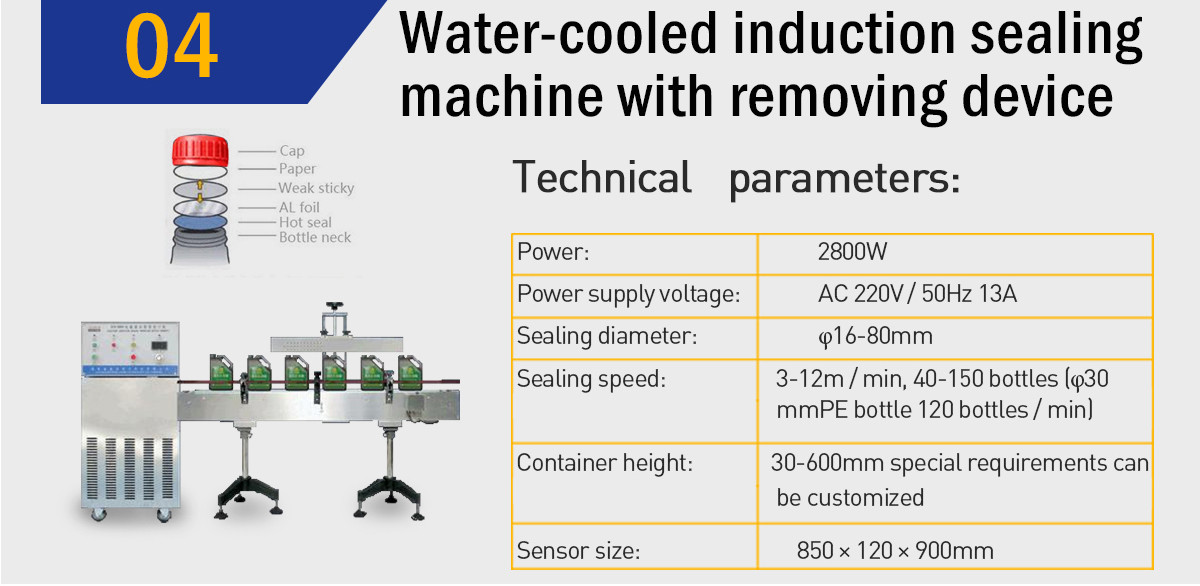

1.Type of Equipment: automatic on-line high-speed sealing machine

2.Control System: transistors modular digital integrated circuit control ground

3.Cooling System: Dual fan, double radiator water cooling system forced circulation

4.sealing effect: the seal intact, one hundred percent. Even a small amount of liquid bottle leaving traces, does not affect the sealing effect.